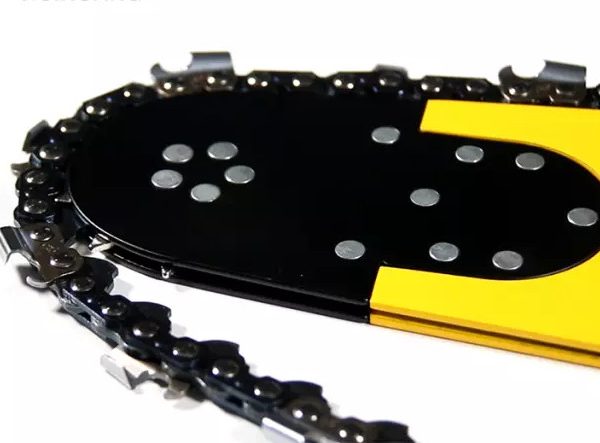

Solid Steel Hard Nose Bar&Chain Combo

Hard nose bars are more tolerant of dirty or abrasive sawing conditions than sprocket nose bars. Such conditions include sawing sandy or muddy wood such as stumps, roots or logs and lumber that have been in ground contact; as well as sawing wood close to the ground, on a beach or at waterline. Running a sprocket nose bar in dirty conditions risks fast wear and clogging or jamming of the sprocket, while a hard nose bar performs reliably.

Advantages of hard nose bars

1 Robustness

The lack of a sprocket makes a hard nose bar more robust than a sprocket nose bar: there is no mechanism or bearing to jam, wear or clog up. This makes the bar more reliable to operate in dirty conditions.

The choice of harder steel alloys for hard nose bars also makes the entire bar less prone to rail wear or damage by bending or twisting.

2 Machinability

A hard nose can also be re-machined or dressed allover to counter the effects of wear. Dressing a worn bar may give it a new quota of runtime and extend its life by many times.

A sprocket nose bar, by contrast, can be only dressed around the side sections, but not the nose, as dressing the nose section would compromise the chain contact on the bar rails. While a worn sprocket nose can be replaced in some bar models, nose wear more often forces you to discard the bar.

3 Chain compatibility

The lack of a nose sprocket makes a hard nose bar compatible with chains of any pitch: there is nothing in the bar that cares about the chain link spacing.

NB. Note that having the correct chain gauge is still necessary.

Downsides of hard nose bars

The hard nose bar obviously comes with a number of drawbacks, of which I list the three most important:

1.Higher Power Draw

Hard nose bars take more saw power to run than standard sprocket nose bars. The reason to this is the sliding chain contact around the tip of a hard nose bar, which applies more frictional drag to the chain than the rolling contact on a sprocket nose bar.

2 Lower allowed chain tension

Hard nose bars often require lower chain tension than sprocket nose bars to counter the higher friction and drag around the bar nose. Low chain tension is not desirable in general as it causes uneven bar wear and sometimes even chain instability.

Finding a low but still safe chain tension for a hard nose bar requires expertise and makes these bars more suited to professional use.

3 High price

The solid, single-piece construction and higher-grade steel material make hard nose bars somewhat more expensive than sprocket nose.

Sprocket nose vs. Hard nose

The short comparison table below gives you a quick overview of the relative properties of hard nose and the standard sprocket nose bars:

| Property | Sprocket nose | Hard nose |

|---|---|---|

| Weight | light–heavy | heavy |

| Friction | low | high |

| Chain tension | optimal | keep low |

| Power demand | low–high | medium–high |

| Cost | lower | higher |

| Applications | most use | dirty conditions construction rescue |

When should I use a hard nose bar?

As a general rule, a hard nose bar is useful in abrasive or dirty conditions. These are conditions where your chain and bar come into contact with sand, soil, gravel, metal or fiber materials, and would include for example:

- Sawing logs that have been lying, rolled or dragged on (sandy) ground

- Logs or lumber that have been embedded in the ground (piles, railroad ties, fence posts, etc.)

- Sawing stumps or roots

- Sawing on a sandy beach (sand will be in the bark)

- Sawing at waterline

- Rescue work: sawing mixed materials